Custom Gas Assisted Molds

CDM Tool & Manufacturing designs and builds custom gas-assisted molds for plastic injection molding. Gas assist molds are a trusted option for improving the production process of large complex parts. Trust a precision mold manufacturer with over 6 decades of successful projects to build your company's injection molds to the tightest of tolerances.

Contact us to get your next custom mold project started.

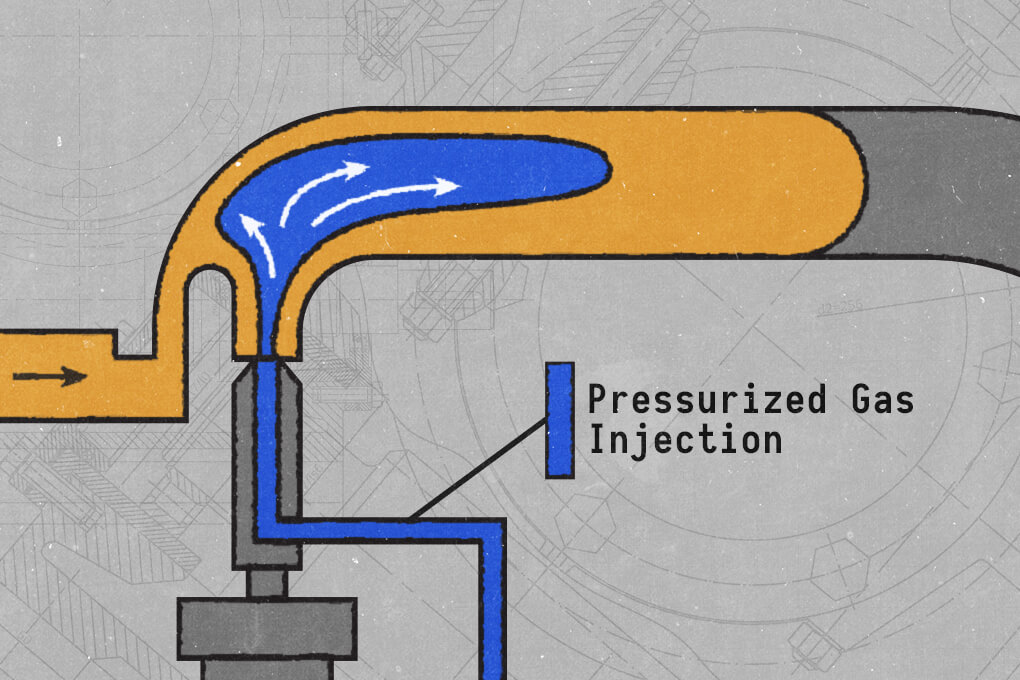

What is Gas-Assisted Injection Molding?

Gas-assisted injection molding is a plastic injection molding process using a controlled volume of pressurized gas to enhance the molding process of large plastic parts. Gas-assisted injection molding starts with injecting plastic material into the mold cavity, leaving the part’s middle section hollow. Pressurized gas is then injected into the hollow section, forcing the plastic material outward and filling the rest of the cavity.

Gas-assisted molds can produce a wide range of plastic parts, including those with complex geometries, thick walls or large surface areas.

Gas-Assisted Molding Advantages

- Reduced cycle time

- Improved part consistency

- Reduced material waste

- Increased design flexibility

Hire an Experienced Gas Assist Mold Designer

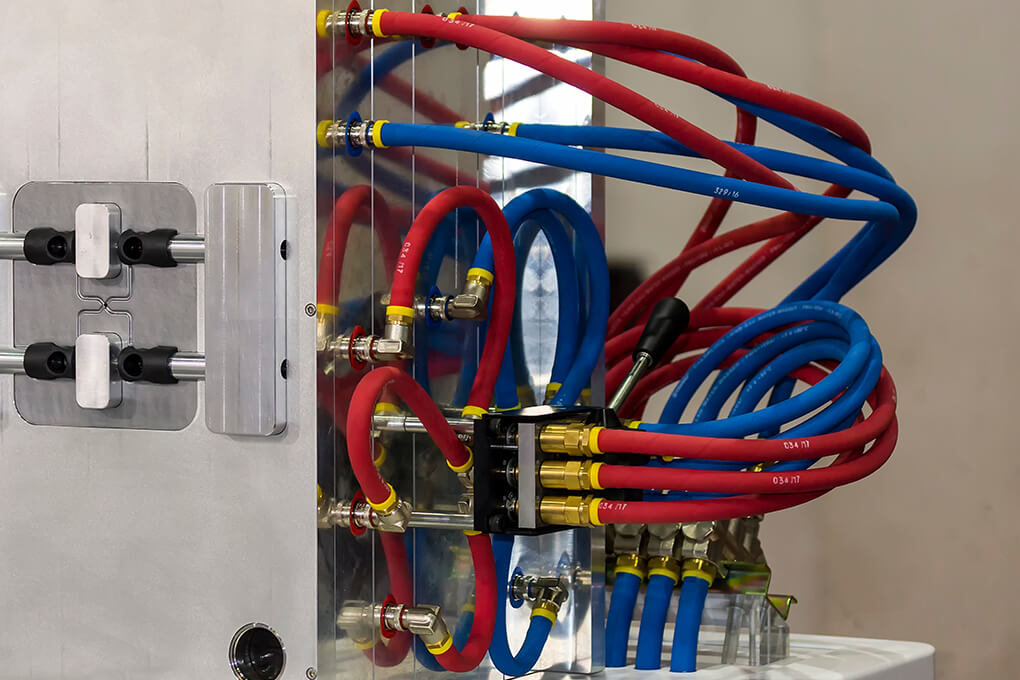

Gas-assisted molds require specialized equipment and expertise not held by many plastic injection molding companies. Thankfully, CDM Tool & Manufacturing’s mold design team has the tools and experience to design gas-assist molds guaranteeing a correct final product. From CAD files to blueprints or specifications - our team can bring your innovative ideas to life no matter how far from completion they are.

CDM Tool & Mfg. Gas Assist Mold Making Capabilities

CDM Tool has a proven track record of delivering precision gas-assisted injection molds, setting us apart from the competition. We manufacture molds with tolerances as tight as 0.0006 over a 140-inch span and 0.0014 over a 23-foot span. While other companies may claim similar capabilities, we demonstrate ours through our work.

Contact us today for a quote on custom gas-assisted injection molds.

Typical Applications for Gas-Assisted Injection Molding

Gas-assisted injection molding is utilized across various industries for producing lightweight, hollow parts with complex designs:

- Agricultural: Tractor control panels and equipment cover necessary durability and reduced weight.

- Transportation: Automotive interior and exterior handles, dashboard panels and steering wheels featuring complex geometries.

- Medical: Large medical equipment housings requiring precision and improved surface finish.

- Construction: Long, hollow structural components and tool handles for high strength and low weight.

- Automation: Industrial equipment covers and control panels designed for durability and efficient material use.

- Electrical: Large printer and copier panels benefit from reduced warpage and enhanced surface quality.

- Hardware: Power tool housings and lawn mower handles emphasizing ergonomics and lightweight design.