Quality Control Services

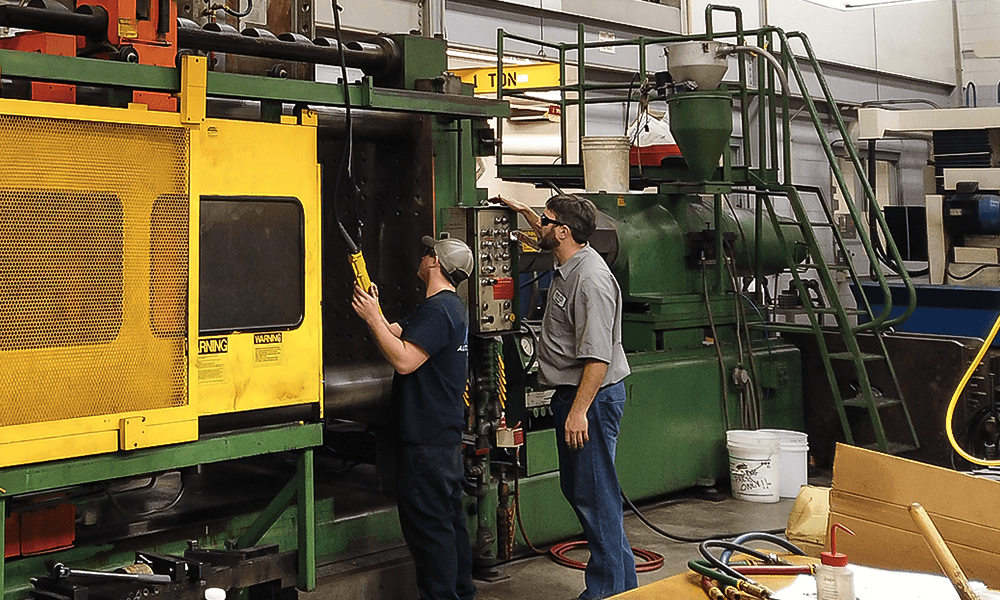

No workpiece is finished until it gets a thorough inspection by one of our toolmakers. Taking the extra time to thoroughly inspect a piece before it goes out to the customer is our way of defending our reputation.

Our finishing and QC capabilities include:

- In-machine probe

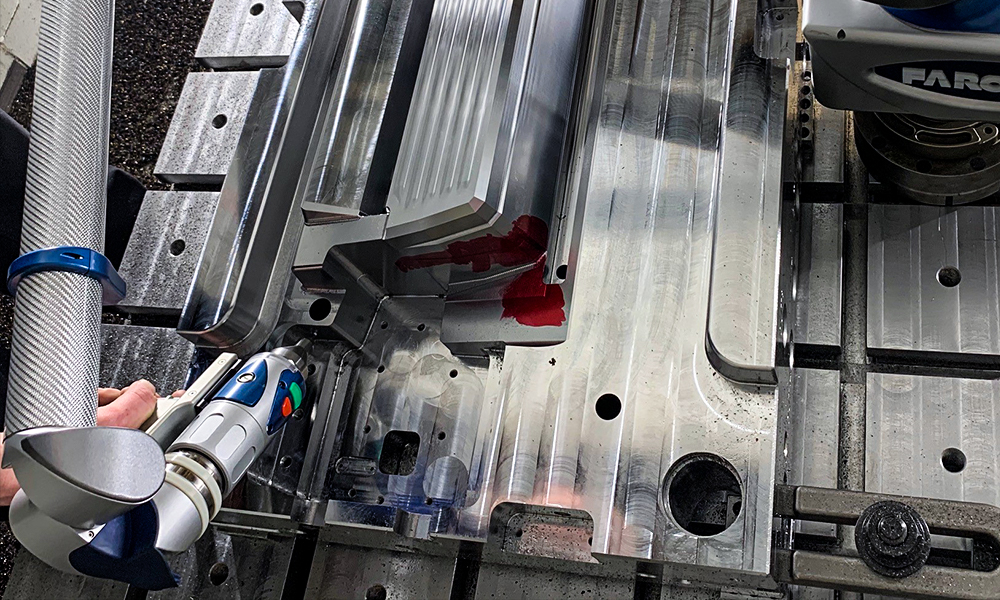

- FARO arm

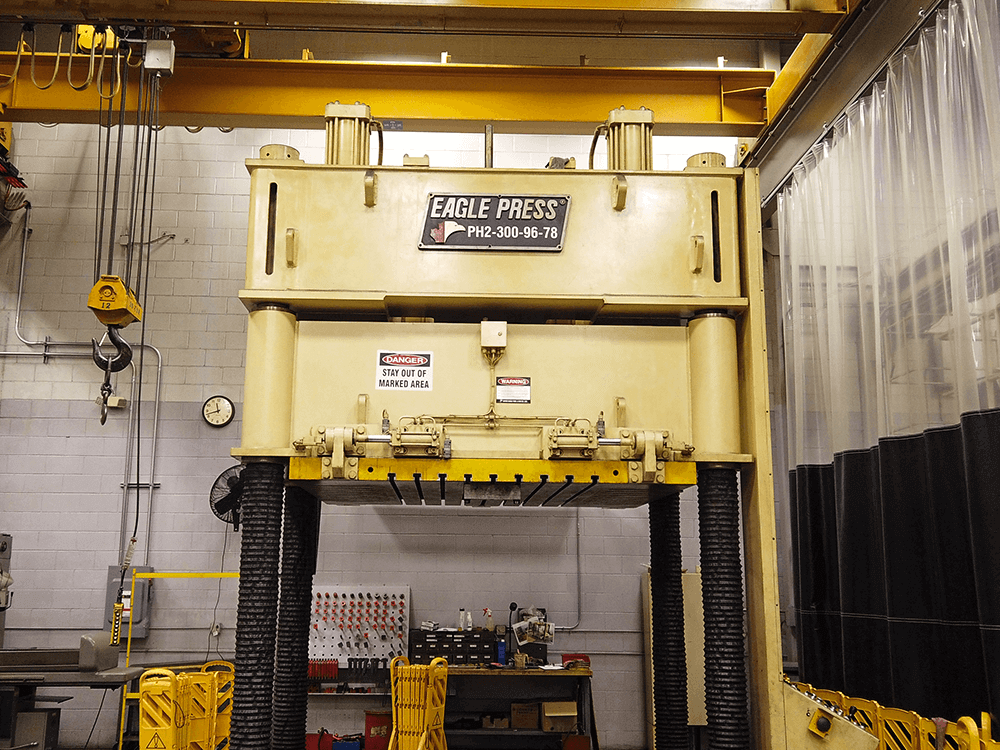

- 300 Ton & 100 Ton Fitting Presses w/ 96x69 inch platens & 78 inches of daylight