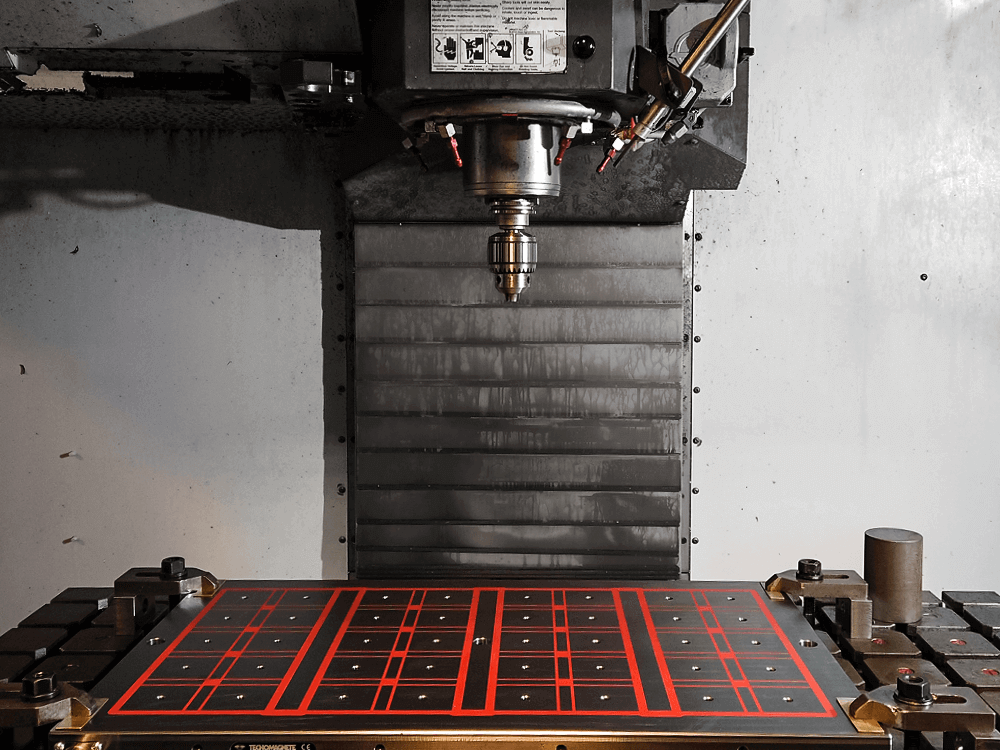

Precision Vertical & Horizontal CNC Milling for Your Projects

At CDM Tool & Manufacturing, our shop is fully equipped to handle your CNC milling service needs, no matter the size or complexity. In addition to machining services like gun drilling, 5-axis machining and sinker EDM, we offer both vertical and horizontal CNC milling. Our mills can manage parts and components weighing up to 22,000 pounds and our extensive inventory of CNC mills allows us to tackle a large volume of projects across a wide range of alloys, sizes and complexities.

By keeping every project in-house-from the first cut to the final inspection, we provide the highest quality and tightest tolerances. Our combination of advanced equipment and skilled machinists enables us to deliver precision-milled parts with accuracy and consistency.

Contact us to learn how our CNC milling services can benefit your next project!

Vertical & Horizontal Milling for Precision Mold Making

CDM Tool uses vertical and horizontal CNC milling to achieve the precision and efficiency required in custom mold manufacturing. Our vertical milling centers excel at producing intricate features, detailed contours and fine surface finishes on mold cores, cavities and inserts. For larger tooling projects, horizontal CNC milling provides greater stability, efficient chip removal and the ability to machine multiple sides of a component in a single setup.

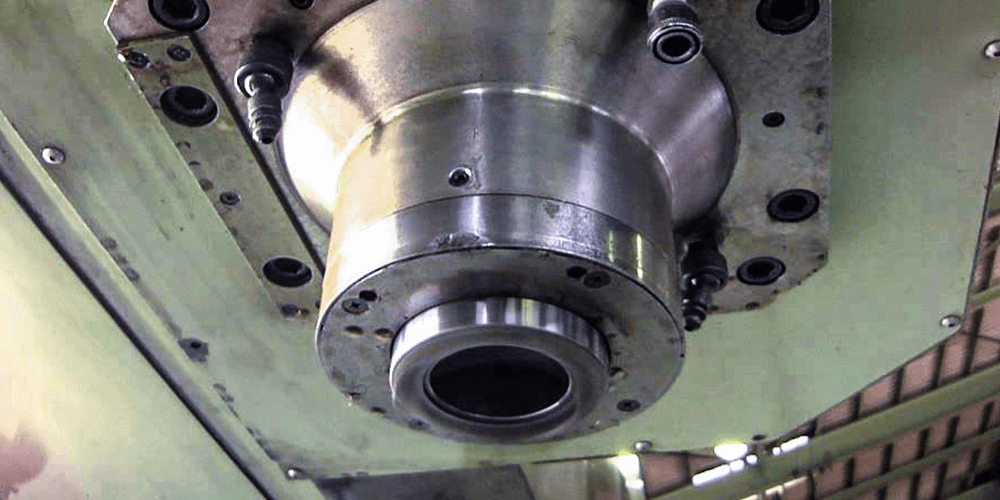

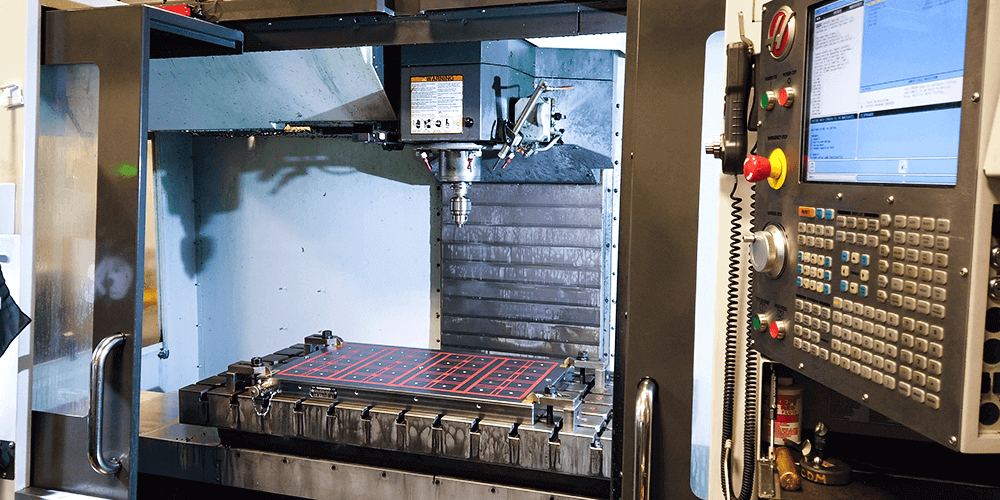

Vertical CNC Milling

Vertical CNC milling uses machines where the spindle is oriented vertically, allowing the cutting tool to move up and down against the workpiece. This setup is ideal for precise drilling, slotting and detailed shaping, especially for smaller parts and jobs requiring high accuracy.

Vertical Milling Advantages

- Lower upfront and operational costs compared to horizontal milling, making it accessible for most shops and customers.

- Easier to operate and maintain, with a larger pool of skilled operators available.

- Best suited for prototypes, custom components and parts with intricate features or detailed surface work.

- Common machine types include turret mills (more versatile) and bed mills (good for basic drilling and grooving).

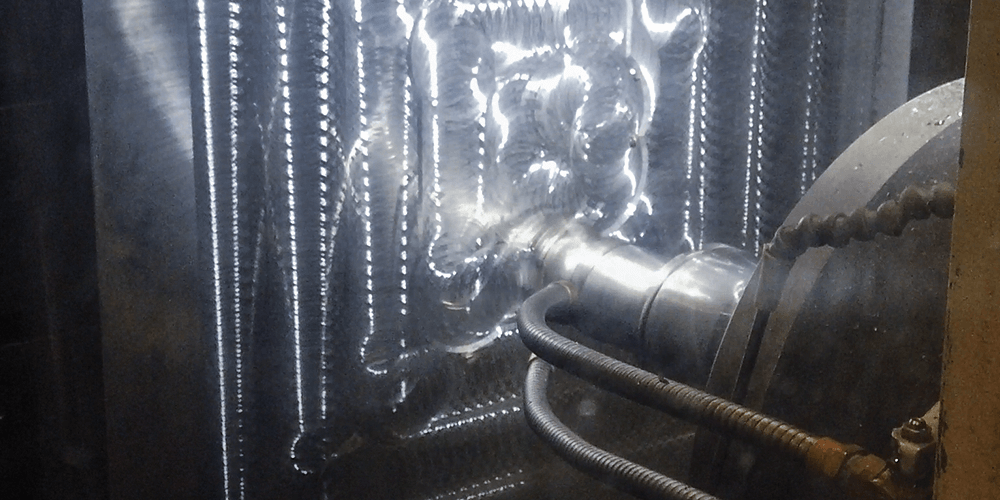

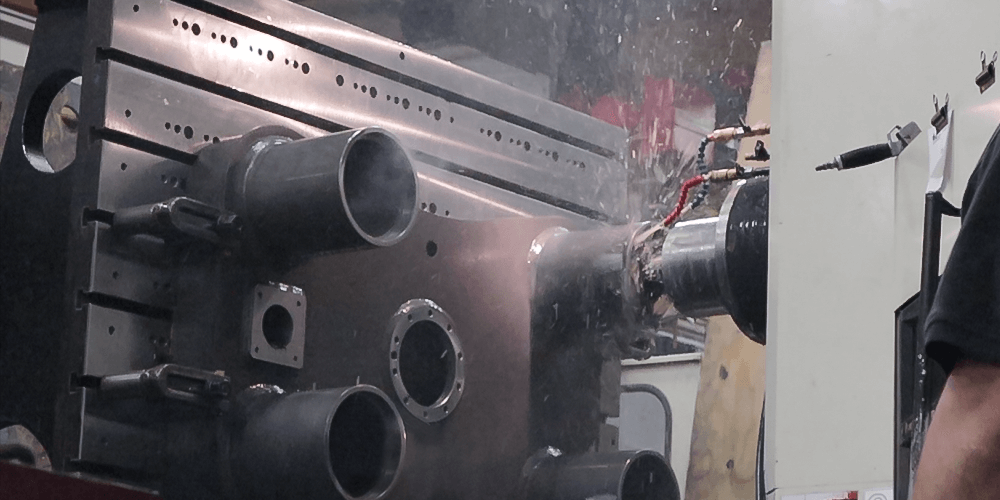

Horizontal CNC Milling

Horizontal CNC milling machines have a spindle oriented horizontally, which allows the cutting tool to move side to side across the workpiece. Horizontal machines use shorter, thicker tools, enabling deeper cuts and efficient removal of large amounts of material, ideal for heavy-duty applications and high-volume production.

Horizontal Milling Advantages

- Capable of handling larger, heavier parts and tougher materials with greater machining power.

- Faster production cycles and the ability to perform multiple cuts in a single pass improve efficiency for large batches.

- Superior for deep grooves, slots and heavy material removal, making them preferred for industrial-scale jobs.

- Typically higher initial investment, but greater efficiency and throughput for large or complex projects.

Our CNC Milling Equipment

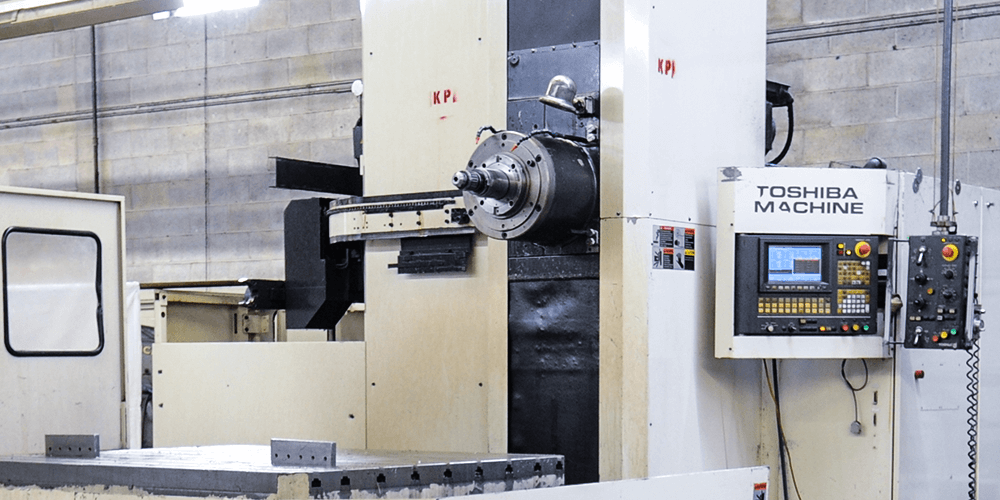

Toshiba BTD-110.R18

-

Machine Type: Horizontal

-

Size: 100 x 80 x 60 x 20W inches

-

Capacity: 22,000 lbs

-

Speed: 4,000 rpm

Toshiba BTD-110.R16

-

Machine Type: Horizontal

-

Size: 79 x 59 x 57 x 16W inches

-

Capacity: 14,000 lbs

-

Speed: 8,000 rpm

Toshiba BTD-13F.R22

-

Machine Type: Horizontal

-

Size: 90 x 118 x 62 x 15W inches

-

Capacity: 22,000 lbs

-

Speed: 8,000 rpm

Toshiba MPF-2614C

-

Machine Type: Vertical

-

Size: 55 x 102 x 34 inches

-

Capacity: 22,000 lbs

-

Speed: 10,000 rpm

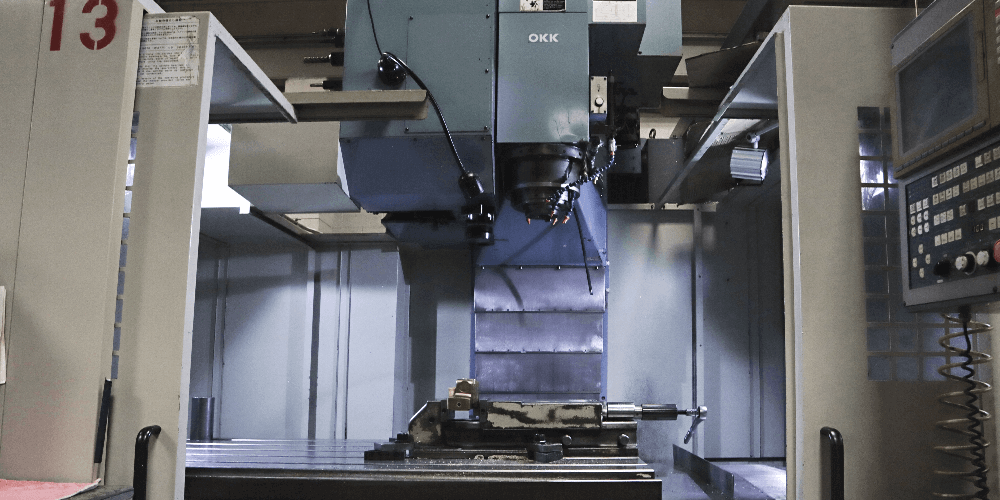

Okk VM-7

-

Machine Type: Vertical

-

Size: 65 x 30 x 27 inches

-

Capacity: 35,000 lbs

-

Speed: 13,000 rpm

Haas VM3 (QTY 2)

-

Machine Type: Vertical

-

Size: 40 x 26 x 25 inches

-

Capacity: 4,000 lbs

-

Speed: 12,000 rpm

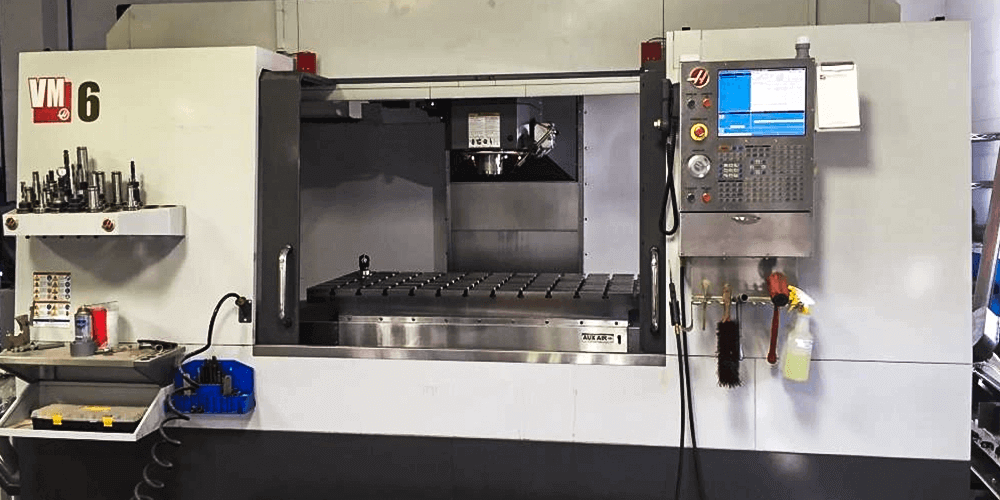

Haas VM6 (QTY 3)

-

Machine Type: Vertical

-

Size: 60 x 28 x 25 inches

-

Capacity: 4,000 lbs

-

Speed: 12,000 rpm

Offering CNC Milling Services to Clients Nationwide

CDM Tool and Mfg provide CNC milling services throughout the country, including the states of Wisconsin, Illinois, Michigan, Minnesota, Iowa, Missouri, Ohio, Indiana, North Carolina, South Carolina, Alabama, Georgia, Kentucky, and more. Get a quote.

Frequently Asked Questions

What is a horizontal CNC machine?

Horizontal CNC machines use a horizontally orientated spindle to shape flat surfaces. Horizontal machines are used in milling operations for the creation of shapes, slots, holes and details of three-dimensional parts.

What is CNC vertical machining?

CNC vertical machining is where a milling machine has vertically oriented spindles to perform plunge cuts and drilling. Vertical machines move along a vertical work plane while fabricating custom shapes, slots, holes and details of three-dimensional parts.

What is the difference between VMC and HMC?

The main difference between vertical machining centers (VMC) and horizontal machining centers (HMC) is the orientation of the spindles. VMCs feature a vertically orientated spindle that performs cuts downward over a vertical plane, whereas HMCs feature a horizontally oriented spindle that cuts downward over a horizontal plane.