Precision Gun Drilling Services for Wisconsin & Nationwide

Hire CDM Tool & Manufacturing’s leading deep hole drilling specialists for your next project. Our precision in-house gun drilling services, powered by state-of-the-art machines and skilled machinists, provide exceptional results for complex projects using advanced techniques.

Why Choose Gun Drilling Services From CDM Tool

- Extreme Precision: Accurate deep holes with high depth-to-width ratios for critical components like manifolds and tubes.

- Versatile Capabilities: Our CNC metal drilling services handle many materials, hole sizes and applications, including pipes and fluid control systems.

- Advanced Technology: Using fluted drills with high-pressure coolant systems, we ensure superior hole quality and surface finish for process cooling channels and more.

- Expert Team: Our experienced gundrillers bring advanced precision hole drilling techniques.

- Comprehensive Solutions: From precision mold making to custom machining, we integrate our in-house gun drilling into complex manufacturing processes for seamless production.

Whether you need micro holes for medical devices, deep cooling channels for automotive molds, or precision drilling for aerospace components, our hole drilling service delivers the precision and quality your project demands. Contact CDM Tool & Manufacturing for a free quote.

What is Gun Drilling?

Gun drilling, also known as precision hole drilling, is a specialized technique for creating deep, straight holes in metal using an elongated, slender cutting tool. As deep hole drilling specialists, we produce holes with high depth-to-diameter ratios, typically ranging from 1 to 50 mm [0.04 to 2.00 in] in diameter, ideal for manifolds, tubes, pipes and fluid control applications.

Unlike traditional twist drills, gun drills feature a single effective cutting edge, enabling efficient chip removal as the tool penetrates deeper. This makes our gun drilling shop perfect for deep hole drilling in industries like the Military, Oil and Gas and Construction.

Benefits of Precision Deep Hole Gun Drilling

- Strong Depth-to-Diameter Ratios: Create holes up to 100 times deeper than their diameter for unique designs in aerospace and automotive components.

- Superior Straightness: Our CNC metal drilling services ensure precise alignment for critical parts like tubes and pipes.

- Next Level Surface Finishes: Achieve smooth inner surfaces, reducing secondary finishing for medical and manufacturing applications.

- Consistent Hole Diameter: Maintain tight tolerances for fluid control systems and process cooling channels.

- Improved Cooling Channels: Enhanced thermal management in manufacturing molds and automotive dies.

- Reduced Tool Wear: High-pressure coolant extends tool life, ensuring consistent results for Oil and Gas projects.

- Minimal Deviation: Straighter holes for military firearm barrels and aerospace instruments.

- Enhanced Part Integrity: Minimize internal stresses to prevent deformation in construction and manufacturing parts.

- Cost-Effective for Long Runs: Our in-house gun drilling offers economies of scale for large manufacturing projects.

Industries We Serve

Our in-house gun drilling and CNC metal drilling services serve many industries.

- Aerospace: Precision holes for lightweight, high-strength components.

- Medical: Micro holes for surgical instruments and implants.

- Automotive: Cooling channels and fluid systems for molds and dies.

- Manufacturing: High-volume production of precision parts like manifolds and tubes.

- Military: Firearm barrels and defense equipment requiring tight tolerances.

- Construction: Durable components for heavy machinery and infrastructure.

- Oil and Gas: Deep holes for exploration and extraction equipment, including pipes and fluid control systems.

Gun Drilling Capabilities From CDM Tool

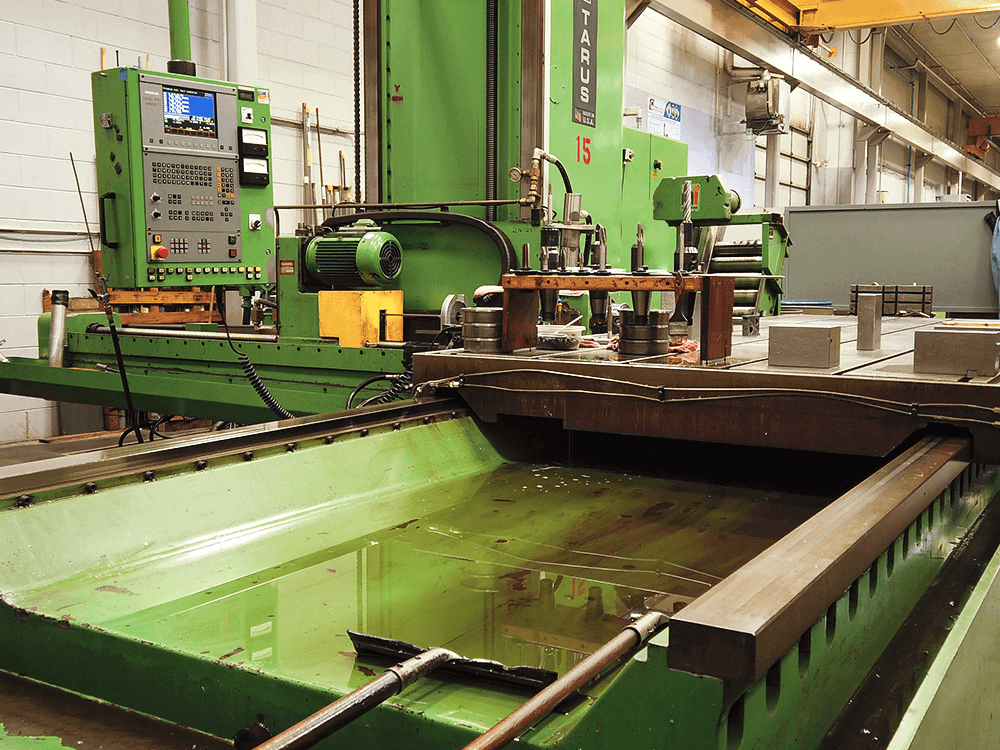

Tarus Gundrill

-

Size: 144 x 54 x 96 inches

-

Depth: 0" - 60"

Size: 0.437" - 0.937" -

Depth: 0" - 48"

Size: 0.281" - 0.421"

And: 1.0" - 1.375" -

Depth: 0" - 24"

Size: 0.187" - 0.312"

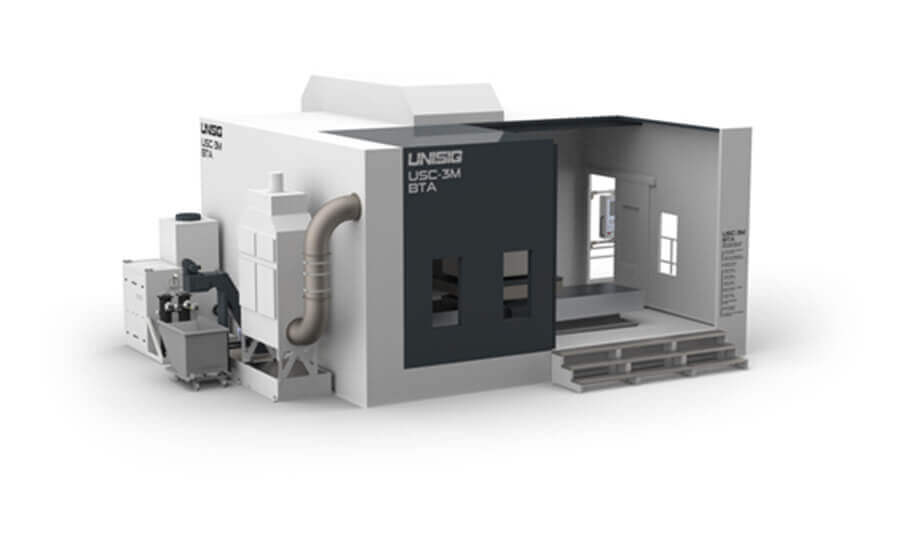

UNISIG USC-3M-BTA

-

Machine Type: 5-Axis and Gun drill

-

Size: 122 x 68.9 x 51.2 inches

-

Tool Capacity: 66,150 lbs

-

Speed: 4,500 RPM

CDM Tool & Manufacturing provides gun drilling for businesses based across Wisconsin, including out of Brookfield, Menomonee Falls, Madison, Milwaukee, West Bend and beyond. We also commonly serve businesses nationwide, including out of Illinois, Michigan, Minnesota, Iowa, Missouri, Ohio, Indiana, North Carolina, South Carolina, Alabama, Georgia, Kentucky and more. Request an estimate.

Frequently Asked Questions

What is gun drilling in machining?

Gundrilling, also known as precision hole drilling, is a machining technique for drilling deep holes beyond the capability of conventional drills. Our gundrilling shop produces holes with high depth-to-diameter ratios, typically 1 to 50 mm [0.04 to 2.00 in], for applications like manifolds, tubes and process cooling systems.

What is a deep hole drilling machine?

A deep hole drilling machine, like our Tarus Gundrill and UNISIG USC-3M-BTA, uses specialized tools with high-pressure coolant to create precise, deep holes. These machines, operated by our experienced gundrillers, excel in applications for Aerospace, Medical and Oil and Gas industries.

What is the gun drilling process?

Gun drilling uses a drill bit with a central hole to deliver high-pressure oil, forcing out excess material during deep cuts. The bit’s unique design aids in chip evacuation, making it ideal for fluid control and process cooling components.