Advanced 5-Axis CNC Machining for Precision Mold Making & Tooling

CDM Tool & Manufacturing brings state-of-the-art 5-axis CNC machining capabilities to revolutionize precision mold-making, custom tooling and prototyping processes. Our advanced machining center ensures your molds, prototypes and custom parts meet the highest standards of quality and accuracy.

Advantages of Our 5 Axis Machining Services

- Enhanced Protection: Our 5-axis precision machining technology allows for intricate designs and tight tolerances that surpass traditional methods.

- Improved Efficiency: By utilizing all 5 axes simultaneously, we complete complex parts in a single setup to reduce protection time and costs.

- Consistent Quality: Our cutting-edge equipment guarantees high-quality results across various materials and geometries.

- Versatile Applications: From aerospace components to medical devices, our 5-axis machining services cater to a wide range of industries.

CDM Tool & Manufacturing combines expert machinists with advanced 5-axis CNC technology to deliver machining capabilities other shops fail to achieve. Get a free quote for your next custom mold or prototyping project from CDM Tool.

What is 5-Axis Machining?

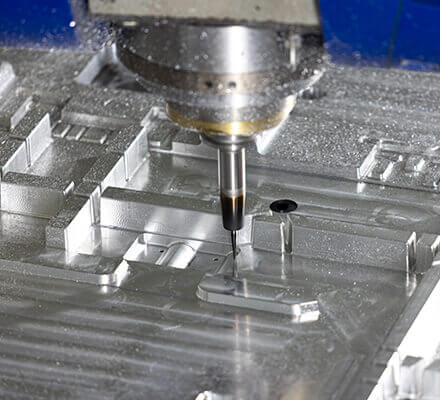

5-axis machining enables a machine to manipulate either a tool or workpiece along five distinct axes at the same time. While conventional machining typically involves three main axes (X, Y, and Z), a 5-axis CNC machine adds two more rotational axes, A and B. This enhanced capability allows the cutting tool to approach the workpiece from multiple angles, significantly expanding the machine's versatility and precision required to produce complex parts.

Benefits of 5-Axis CNC Machining Services

- Complex Geometries: Create intricate shapes and contours 3-axis machining can’t and open up new design possibilities for your projects.

- Single-Setup Efficiency: Reduce setup time and improve accuracy by machining multiple sides of a part in one operation to minimize human error and part handling.

- Superior Surface Finish: Achieve smoother surfaces and better detail by maintaining optimal tool-to-part contact to reduce the need for post-processing.

- Shorter Lead Times: Complete projects faster with fewer setups and tool changes, increasing productivity and reducing time-to-market for your products.

- Cost-Effective for Small Batches: Produce small runs or prototypes more economically, as the reduced setup time makes short production cycles viable.

- Enhanced Accuracy: Maintain tight tolerances consistently across complex parts to ensure precision in every design aspect.

- Improved Chip Evacuation: Better chip removal in deep pockets and complex cavities, resulting in superior surface quality and reduced thermal damage.

- Flexibility for Future Projects: Invest in versatility with a 5-axis machine capable of handling diverse future job requirements and part complexities.

Experience the benefits of 5-axis machining firsthand with CDM Tool & Manufacturing's advanced 5-axis CNC machining services. We bring your complex designs to life with unparalleled precision and efficiency.

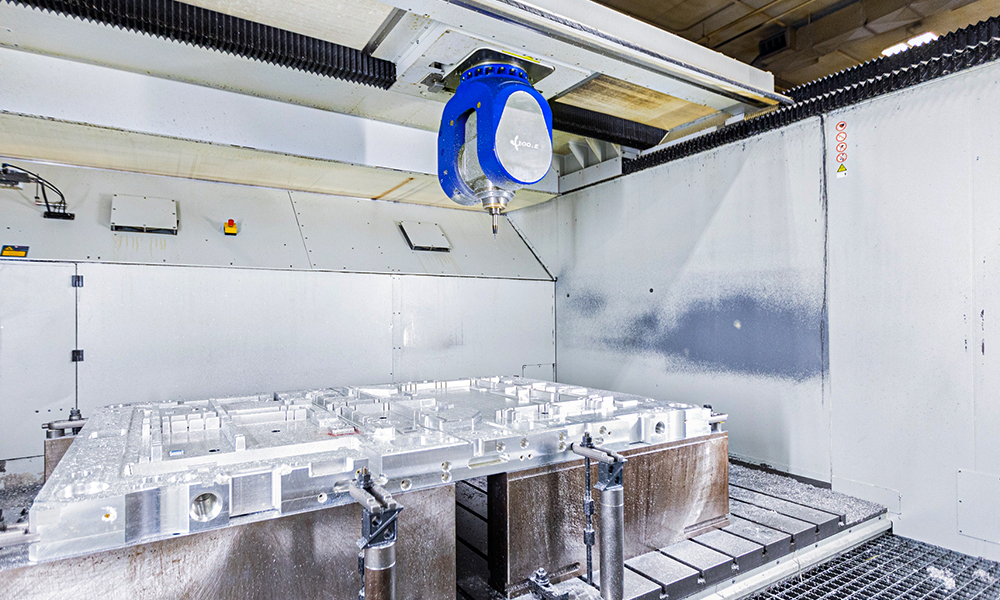

Our Five Axis Equipment

Fooke Endura 704 Linear 5 Axis

-

Machine Type: 5 axis

-

Size: 86 x 138 x 59 inches

-

Capacity: 60,000 lbs

-

Speed: 24,000 RPM

FPT Pragma

-

Machine Type: 5 axis

-

Size: 275 x 78 x 47 inches

-

Capacity: 60,000 lbs

-

Speed: 18,000 RPM

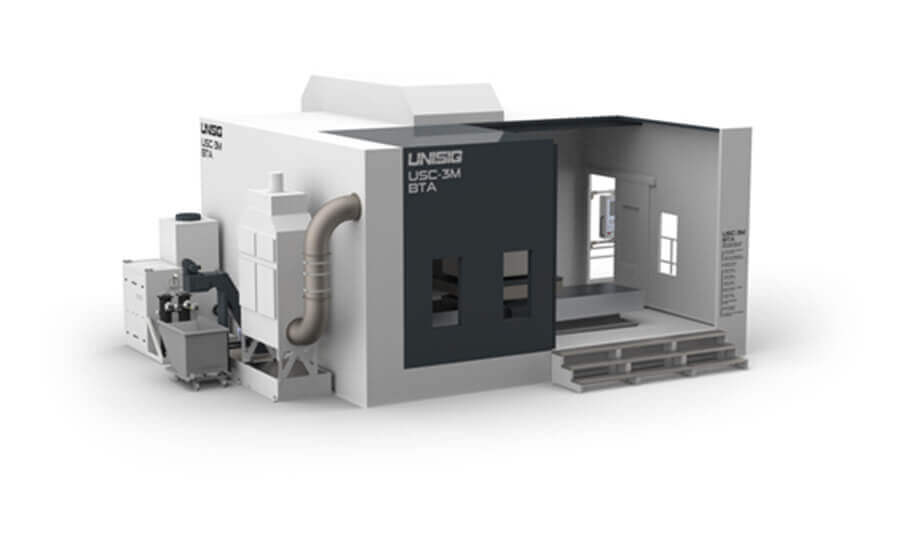

UNISIG USC-3M-BTA

-

Machine Type: 5-Axis and Gun drill

-

Size: 122 x 68.9 x 51.2 inches

-

Tool Capacity: 66,150 lbs

-

Speed: 4,500 RPM

CDM Tool & Mfg provides advanced milling equipment for mold making & prototyping across the country, including the states of Wisconsin, Illinois, Michigan, Minnesota, Iowa, Missouri, Ohio, Indiana, North Carolina, South Carolina, Alabama, Georgia, Kentucky, and more. Request a quote.

Frequently Asked Questions

What is a five-axis CNC?

Five-axis CNC involves using a computer numerically controlled machine to make cuts across five directions. Five-axis CNC machines use a cutting tool that moves along the X, Y, and Z axes and rotates along the A and B axes.

What is the difference between 3-axis and 5-axis CNC?

While three-axis CNC machines move along the X, Y, and Z axes, five-axis machines additionally rotate over the A and B axes. Three-axis machining is known to be simpler, while five-axis machining requires more preparation but less material handling.

What are the advantages of 5-axis machining services?

One of the main advantages of five-axis machines is they do not require workpieces to be repositioned during operation. Machining most or all features in the same setup helps to ensure precision and accuracy for tight tolerance features. And the added time savings can have a dramatic positive effect on larger-scale production runs. Five-axis machining can also save cost due to its fewer required specialty tools and extensions.