Custom Structural Foam Mold Design & Manufacturing

Structural foam molding requires tooling engineered for strength, precision and part consistency. CDM Tool & Manufacturing designs and builds structural foam molds tailored for thick-walled, large-format plastic components. As a trusted Wisconsin injection mold maker, we support OEMs and industrial clients with custom tooling built for durability and efficient part production. Our team collaborates directly with your engineers to refine designs, prevent internal voids and control surface finish across large part geometries.

CDM Tool & Mfg. Structural Foam Mold Making Capabilities

CDM Tool manufactures custom tooling designed specifically for structural foam molding. Our molds support applications using gas-assist and chemical blowing agents and are engineered to handle oversized parts without compromising dimensional accuracy or cycle time.

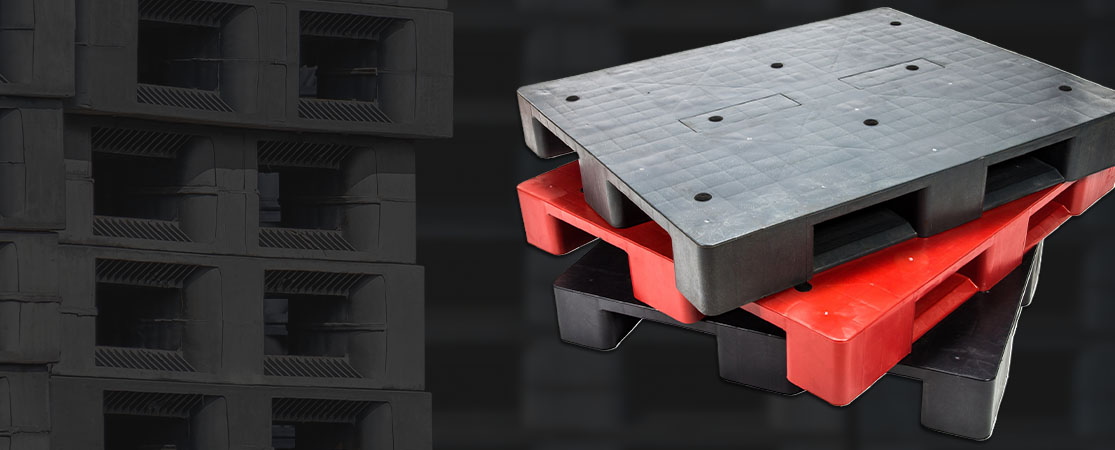

We supply industrial molds for bulk part production across various applications, including pallets, panels, enclosures and housings. Whether you're launching a new part or upgrading an existing mold, we deliver precision tooling made to perform under demanding structural foam molding conditions.

Our Structural Foam Mold Design Process

Every structural foam mold we design is tailored for part behavior, material flow and wall thickness variability. CDM’s experienced design engineers use advanced CAD modeling and simulation software to optimize gate placement, venting and cooling layout specific to structural foam characteristics.

We prioritize durability, fill consistency and smooth release from the earliest design reviews to final machining. Our structural foam molds are built for repeated use, long production life and minimal maintenance.

Benefits of Structural Foam Molding Tooling

Structural foam molding reduces material usage while producing rigid, lightweight parts with excellent strength-to-weight ratios. Unlike traditional high-pressure molding, structural foam processes require specially designed molds to accommodate controlled foaming and internal expansion.

Our Molds Help Manufacturers Achieve:

- Consistent wall thickness with minimal warp or sink

- Lightweight yet rigid parts for industrial performance

- Reduced tooling stress and extended mold life

- Efficient production of large plastic parts

Applications for Structural Foam Molds

CDM Tool supplies custom-designed molds used by structural foam part manufacturers across a range of industries:

- Material Handling: Pallets, bins and storage containers

- Automotive: Under-hood and interior panels with structural reinforcement

- Construction: Wall panels, insulation housings and utility boxes

- Appliances: Lightweight but strong internal and external housings

- Agricultural Equipment: Large protective covers and enclosures for outdoor use

Why Choose CDM Toolfor Structural Foam Mold Manufacturing?

With over 60 years of experience, CDM Tool is a trusted mold designer and manufacturer for complex structural foam applications. We specialize in custom tooling for large, low-pressure parts requiring durable, repeatable molds.

Our engineering and design team supports every stage of mold development—from part feasibility to final build—giving manufacturers confidence in every cycle. Each mold is produced in-house using CNC and EDM technology, guaranteeing high-precision results for high-performance parts.

Choose CDM Tool for:

- Fully custom mold designs for structural foam processes

- Engineering collaboration to reduce defects and material waste

- Tooling built for large parts and long production runs

- Proven support for industrial and OEM part suppliers

- Wisconsin-based mold manufacturing with nationwide reach

Contact CDM Tool to Start Your Structural Foam Mold Project

CDM Tool & Manufacturing delivers industrial-grade structural foam molds designed to perform under pressure. Contact us today to speak with our mold-making team or request a quote.