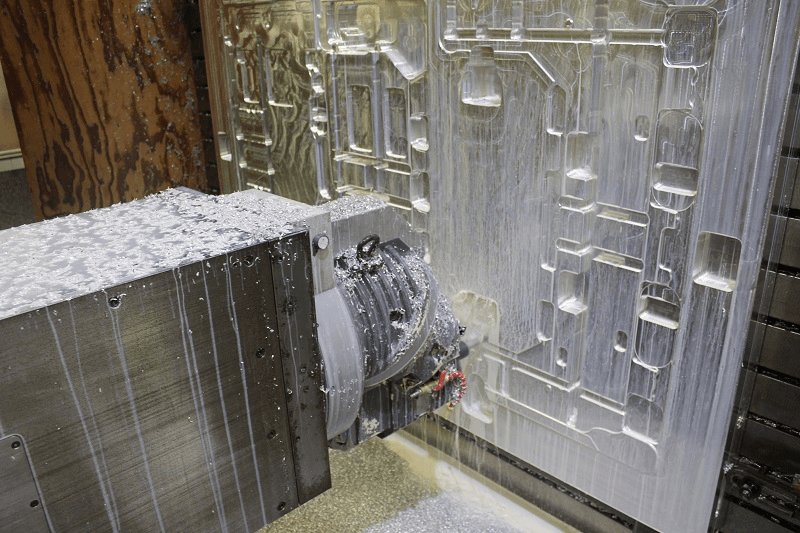

High-Pressure Injection Molds for Your Exact Needs

When choosing a high-pressure injection mold manufacturer, precision is key. You need a manufacturer who can achieve the right tolerances and flow rates for your applications with accuracy and care. CDM Tool & Manufacturing works side-by-side with your engineers to create prototypes, offer design considerations, solve potential defects and get your high-pressure injection molds in your hands on schedule.

CDM Tool & Mfg. High-Pressure Mold Making Capabilities

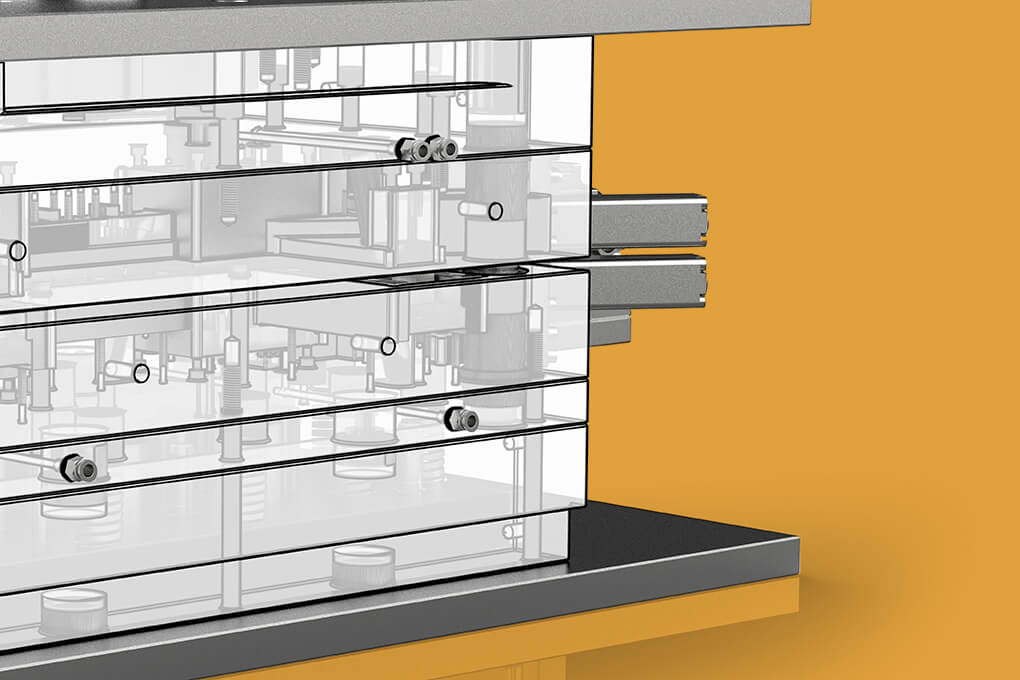

At CDM Tool & Manufacturing, our advanced mold-making capabilities cater specifically to high-pressure injection molding applications. Our state-of-the-art facility features cutting-edge technology and machinery, enabling us to produce molds with exceptional precision and efficiency.

We specialize in prototype and production molds tailored to your needs, whether you need a new product or are scaling up production. Our experienced engineers utilize advanced design software and manufacturing techniques to create molds up to par with rigorous industry standards. With a commitment to quality control at every production stage, we consistently deliver high-performance high-pressure injection molds.

Custom High-Pressure Mold Design Process

At CDM Tool & Manufacturing, our custom mold design process focuses on high-pressure applications to meet unique client needs. We collaborate closely with your engineering team to grasp specific requirements and challenges. Our skilled designers use advanced CAD software to create detailed models, allowing for precise visualization before production begins.

Critical factors like material selection, tolerances and manufacturability are considered throughout the design phase. This approach promotes efficient production while minimizing potential issues during molding. By emphasizing innovation and quality, we bring your ideas to life with molds crafted for optimal performance in high-pressure environments.

Benefits of High-Pressure Injection Molding

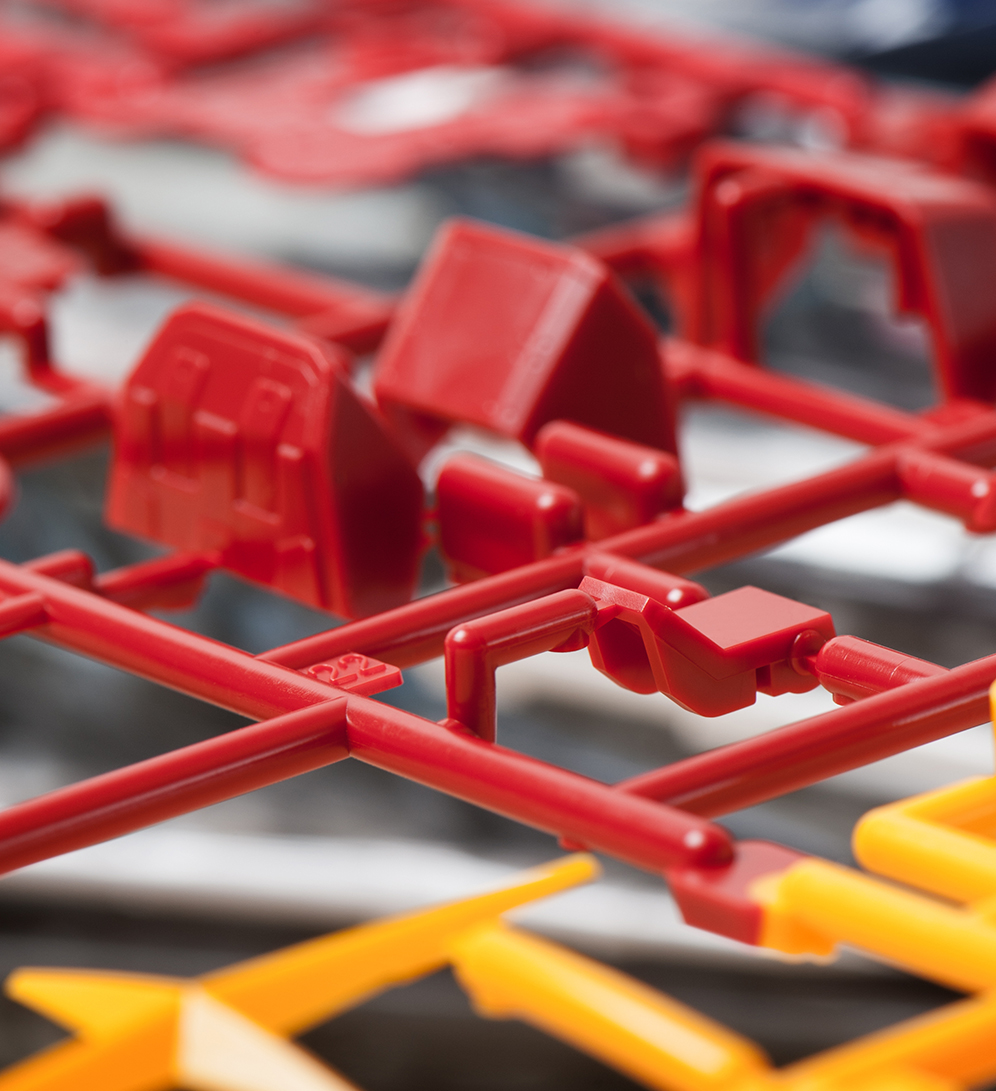

High-pressure injection molding allows the incorporation of small details into your mold designs without the high cost of other methods. This process is highly accurate and cost-effective with high reproducibility, making it ideal for simplified quality control.

Additionally, high-pressure injection molding facilitates easy color integration. There is minimal waste since unused materials can often be remelted and reused.

Applications for High-Pressure Injection Molding

High-pressure injection molds are ideal for applications across most industries, meet high-volume demands and yield consistent shapes with gloss-like finishes without additional finishing. High-pressure injection molds are commonly used in the construction, automotive, agricultural, consumer goods, telecommunications, food & beverage, medical and engineering industries.

Contact CDM Tool to Create Your High-Pressure Molds

Don’t let the pressure of shopping around for the perfect mold slow you down. CDM Tool & Manufacturing specializes in designing and manufacturing meticulously crafted high-pressure injection molds to make your business a success. Call us with questions or contact us to get started with a quote. We're the mold-making company you can trust to get it done right the first time, all the time.